Model number

0.4\6.6\10\11kV Cast Resin Dry Type Transformer

● Voltage: 0.4kV, 6kV to 11kV ● Capacity: 30kVA to 2500kVA ● Model: SC(B)12、SC(B)14、SC(B)18

Categories:

Dry-type Transformer

Product Overview

SC(B) series epoxy casting dry-type transformer produced by Ruier Electric is a kind of mechanical strength, electrical strength, heat-resistant dry-type transformer with filler F-class epoxy resin mixture, after vacuum film degassing, under vacuum and pressure, thin-layer casting inside and outside the surface of the high and low voltage coils reinforced by glass wire molding network, presenting a kind of mechanical strength, electrical strength, heat-resistant degree of dry-type transformer is very high. Ruier Electric adopts advanced production equipment, assured raw materials, scientific management, advanced technology, strict testing methods, so that the quality and performance of the products to reach the international level.

Product Overview

Rated capacity | VoltageCombination | Linkage group labeling | Impedance voltage

| Transformer weight | Transformer reference size (mm) | Housing reference size(mm) | No-load loss | Load Loss | ||

High Voltage(kV) | Low Voltage (kV) | |||||||||

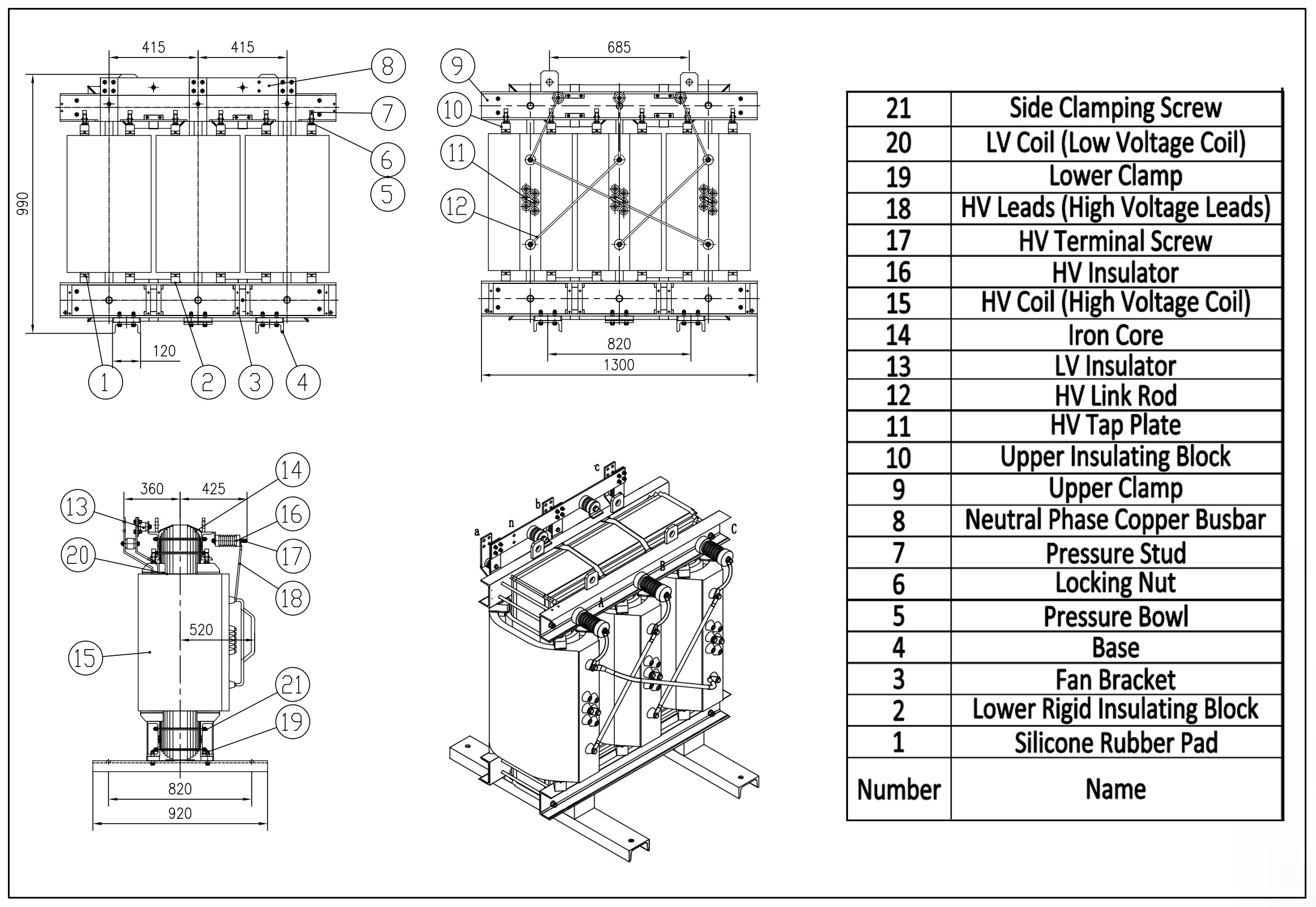

SC12-30 | 30 | 6 | 0.4 | Dyn11 | 4 | 0.25 | 680*450*640 | 1100*850*1040 | 150 | 710 |

SC12-50 | 50 | 0.3 | 700*450*640 | 1260*850*1150 | 215 | 1000 | ||||

SC12-80 | 80 | 0.43 | 860*450*760 | 1500*1300*2200 | 295 | 1380 | ||||

SC12-100 | 100 | 0.63 | 920*780*900 | 1500*1300*2200 | 320 | 1570 | ||||

SC12-125 | 125 | 0.7 | 920*780*950 | 1500*1300*2200 | 375 | 1850 | ||||

SC12-160 | 160 | 0.8 | 920*780*1000 | 1800*1300*2200 | 430 | 2130 | ||||

SC12-200 | 200 | 0.95 | 1100*780*1000 | 1800*1300*2200 | 495 | 2530 | ||||

SC12-250 | 250 | 1.1 | 1100*650*1150 | 1800*1300*2200 | 575 | 2760 | ||||

SC12-315 | 315 | 1.3 | 1100*940*1150 | 1800*1300*2200 | 705 | 3470 | ||||

SCB12-400 | 400 | 1.5 | 1100*940*1200 | 2000*1500*2200 | 785 | 3990 | ||||

SCB12-500 | 500 | 2 | 1350*940*1200 | 2000*1500*2200 | 930 | 4880 | ||||

SCB12-630 | 630 | 205 | 1350*940*1300 | 2000*1500*2200 | 1070 | 5880 | ||||

SCB12-630 | 630 | 6 | 205 | 1400*940*1130 | 2000*1500*2200 | 1040 | 5960 | |||

SCB12-800 | 800 | 2.35 | 1450*940*1140 | 2000*1500*2200 | 1215 | 6960 | ||||

SCB12-1000 | 1000 | 2.75 | 1500*940*1250 | 2000*1600*2200 | 1415 | 8130 | ||||

SCB12-1250 | 1250 | 3.1 | 1500*940*1300 | 2000*1600*2200 | 1670 | 9690 | ||||

SCB12-1600 | 1600 | 3.6 | 1500*940*1410 | 2200*1600*2200 | 1960 | 11730 | ||||

SCB12-2000 | 2000 | 4.6 | 1650*1190*1780 | 2200*1600*2200 | 2440 | 14450 | ||||

SCB12-2500 | 2500 | 5.5 | 1720*1190*1800 | 2200*1600*2200 | 2880 | 17170 | ||||

Model number | Rated capacity | VoltageCombination | Linkage group labeling | Impedance voltage

| Transformer weight | Transformer reference size (mm) | Housing reference size(mm) | No-load loss | Load Loss | |

High Voltage(kV) | Low Voltage (kV) | |||||||||

SC14-30 | 30 | 6 | 0.4 | Dyn11 | 4 | 0.28 | 680*450*640 | 1100*850*1040 | 130 | 640 |

SC14-50 | 50 | 0.33 | 700*450*640 | 1260*850*1150 | 185 | 900 | ||||

SC14-80 | 80 | 0.47 | 860*450*760 | 1500*1300*2200 | 250 | 1240 | ||||

SC14-100 | 100 | 0.7 | 920*780*900 | 1500*1300*2200 | 270 | 1415 | ||||

SC14-125 | 125 | 0.77 | 920*780*950 | 1500*1300*2200 | 320 | 1665 | ||||

SC14-160 | 160 | 0.88 | 920*780*1000 | 1800*1300*2200 | 365 | 1915 | ||||

SC14-200 | 200 | 1.03 | 1100*780*1000 | 1800*1300*2200 | 420 | 2275 | ||||

SC14-250 | 250 | 1.2 | 1100*650*1150 | 1800*1300*2200 | 490 | 2485 | ||||

SC14-315 | 315 | 1.43 | 1100*940*1150 | 1800*1300*2200 | 600 | 3125 | ||||

SCB14-400 | 400 | 1.65 | 1100*940*1200 | 2000*1500*2200 | 665 | 3590 | ||||

SCB14-500 | 500 | 2.1 | 1350*940*1200 | 2000*1500*2200 | 790 | 4390 | ||||

SCB14-630 | 630 | 2.25 | 1350*940*1300 | 2000*1500*2200 | 910 | 5290 | ||||

SCB14-630 | 630 | 6 | 2.25 | 1400*940*1130 | 2000*1500*2200 | 885 | 5365 | |||

SCB14-800 | 800 | 2.6 | 1450*940*1140 | 2000*1500*2200 | 1035 | 6265 | ||||

SCB14-1000 | 1000 | 3 | 1500*940*1250 | 2000*1600*2200 | 1205 | 7315 | ||||

SCB14-1250 | 1250 | 3.4 | 1500*940*1300 | 2000*1600*2200 | 1420 | 8720 | ||||

SCB14-1600 | 1600 | 3.95 | 1500*940*1410 | 2200*1600*2200 | 1665 | 10555 | ||||

SCB14-2000 | 2000 | 5.1 | 1650*1190*1780 | 2200*1600*2200 | 2075 | 13005 | ||||

SCB14-2500 | 2500 | 6 | 1720*1190*1800 | 2200*1600*2200 | 2450 | 15445 | ||||

Model number | Rated capacity | VoltageCombination | Linkage group labeling | Impedance voltage

| Transformer weight | Transformer reference size (mm) | Housing reference size(mm) | No-load loss | Load Loss | |

High Voltage(kV) | Low Voltage (kV) | |||||||||

SC18-30 | 30 | 6 | 0.4 | Dyn11 | 4 | 0.28 | 680*450*640 | 1100*850*1040 | 105 | 640 |

SC18-50 | 50 | 0.33 | 700*450*640 | 1260*850*1150 | 155 | 900 | ||||

SC18-80 | 80 | 0.4 | 860*450*760 | 1500*1300*2200 | 210 | 1240 | ||||

SC18-100 | 100 | 0.7 | 920*780*900 | 1500*1300*2200 | 230 | 1415 | ||||

SC18-125 | 125 | 0.77 | 920*780*950 | 1500*1300*2200 | 270 | 1665 | ||||

SC18-160 | 160 | 0.88 | 920*780*1000 | 1800*1300*2200 | 310 | 1915 | ||||

SC18-200 | 200 | 1.03 | 1100*780*1000 | 1800*1300*2200 | 360 | 2275 | ||||

SC18-250 | 250 | 1.2 | 1100*650*1150 | 1800*1300*2200 | 415 | 2485 | ||||

SC18-315 | 315 | 1.43 | 1100*940*1150 | 1800*1300*2200 | 510 | 3125 | ||||

SCB18-400 | 400 | 1.65 | 1100*940*1200 | 2000*1500*2200 | 570 | 3590 | ||||

SCB18-500 | 500 | 2.1 | 1350*940*1200 | 2000*1500*2200 | 670 | 4390 | ||||

SCB18-630 | 630 | 2.25 | 1350*940*1300 | 2000*1500*2200 | 775 | 5290 | ||||

SCB18-630 | 630 | 6 | 2.25 | 1400*940*1130 | 2000*1500*2200 | 750 | 5365 | |||

SCB18-800 | 800 | 2.6 | 1450*940*1140 | 2000*1500*2200 | 875 | 6265 | ||||

SCB18-1000 | 1000 | 3 | 1500*940*1250 | 2000*1600*2200 | 1020 | 7315 | ||||

SCB18-1250 | 1250 | 3.4 | 1500*940*1300 | 2000*1600*2200 | 1205 | 8720 | ||||

SCB18-1600 | 1600 | 3.95 | 1500*940*1410 | 2200*1600*2200 | 1415 | 10555 | ||||

SCB18-2000 | 2000 | 5.1 | 1650*1190*1780 | 2200*1600*2200 | 1760 | 13005 | ||||

SCB18-2500 | 2500 | 6 | 1720*1190*1800 | 2200*1600*2200 | 2080 | 15445 | ||||

Product Characteristics

(1) Performance characteristics

- is safe, fireproof, non-polluting, and can run directly in the load center;

- High mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability and long service life;

- Low loss, low noise, obvious energy saving effect, maintenance free;

- Good heat dissipation performance, strong overload capacity, and capacity increase operation when forced air cooling;

- good moisture-proof performance, adapted to operate in high humidity and other harsh environments;

- can be equipped with perfect temperature detection and protection system. Adopting intelligent signal temperature control system, it can automatically detect and itinerantly display the working temperature of each of the three-phase windings, and it can automatically start and stop the fan with alarm, trip and other function settings;

- small size, light weight, occupies less space, low installation cost.

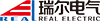

(2) Structural features:

- iron core selection of cold rolled silicon steel sheet, 45 degree disintegration safety oblique joint structure, the use of three shear two punch core de-angled transverse shear process and five-step step shear and stacked iron process, improve the flux distribution at the joints, reducing the vibration energy of the core. The core is cured in one piece and the surface is sealed with insulating resin, which effectively reduces no-load loss, no-load current and core noise;

- high voltage coils are wound with copper conductors with F-class insulation and international insulating materials, and larger capacity coils are equipped with heat dissipation air channels along the axial direction. This structure has good resistance to current impact, temperature change, cracking and good heat dissipation. Adopting multi-stage segmented cylindrical structure, it has strong ability to withstand over-voltage and very low partial discharge level. The coils are molded and cast after vacuum drying, the whole casting and curing process is completed according to the pre-programmed process curve, and the precise process control ensures that the coils are free of air holes and cavities;

- low-voltage coils can adopt foil structure, which effectively solves the problem of ampere-turn imbalance of low-voltage and high-current coils adopting wire-winding type; meanwhile, foil coils do not have axial turns and axial winding spiral angle, which effectively eliminates the axial force of transformer during short-circuiting, and ensures that the current density inside the coil can be adjusted axially freely according to the distribution of load of high-voltage coils, and reduce the radial force during sudden low-voltage short-circuit. After winding, the coil ends are sealed and cured with resin, which avoids the entry of all kinds of foreign matter and moisture.

Key words:

Get A Quote

Leave your contact information and get a free product quote

Solution

Become a leader in the power distribution industry in the intelligent era

Related Products

The company mainly operates transformer and distribution equipment such as screens, desks, cabinets, and boxes, as well as transformer and distribution equipment, transformers, switches, automation control systems, etc

● Model: SC(B)12、SC(B)14、SC(B)18 ● Capacity: 30kVA to 2500kVA ● Voltage: 0.4kV, 6kV to 11kV

10kV Three-dimensional Rolled Iron Core Transformer

● Voltage: 400V, 6kV to 10kV ● Capacity: 30kVA to 2500kVA ● Model: S13、S20、S22

0.4\6.6\10\11kV Cast Resin Dry Type Transformer

● Voltage: 0.4kV, 6kV to 11kV ● Capacity: 30kVA to 2500kVA ● Model: SC(B)12、SC(B)14、SC(B)18