10kV Hermetically Sealed Oil Immersed Transformer 1250kVA

● Voltage: 400V/6.6kV/10kV ● Capacity: 30 /200/400/630/2500kVA ● Model: S13、S11

Categories:

Oil-immersed Transformer

Product Overview

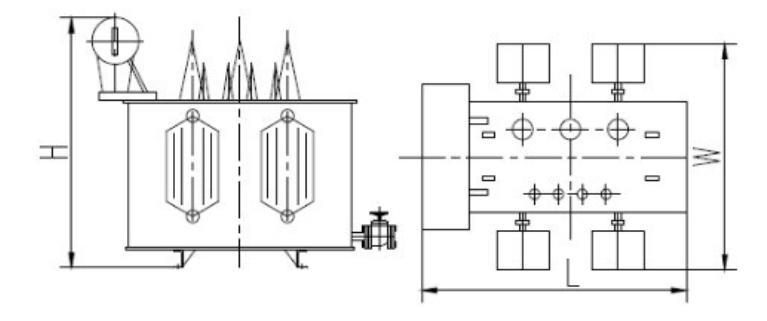

Oil-immersed stacked iron core transformer adopts classic stacked iron core design, mature technology, stable and reliable operation, with insulating oil as insulation medium, composed of iron core, coil, regulator switch, oil tank and other components of the electrical appliances to change the voltage and transmission of alternating current energy. Iron core and winding structure is solid, strong short-circuit resistance, adapt to a variety of complex working conditions. It is characterized by small volume, cheap price and strong weather resistance. The structure form is flexible and diversified, beautiful appearance, can meet the needs of different users.

Application scenario

S11 series 20kV three-phase oil-immersed transformer | ||||||||

Model | Voltage Combination(kVA) | Typical Voltage Combinations(kV) | Linkage group labeling | Impedance Voltages(%) | total weight(t) | Reference Size(mm) L*W*H | No-load loss (W) | Load Loss |

S11-30/20 | 30 | High Voltage | Dyn11 | 4 | 0.9 | 1200*950*1400 | 100 | 690/660 |

S11-50/20 | 50 | 4.5 | 1 | 1200*950*1500 | 130 | 1010/960 | ||

S11-63/20 | 63 | 1.1 | 1200*950*1500 | 150 | 1200/1150 | |||

S11-80/20 | 80 | 1.2 | 1200*950*1600 | 180 | 1440/1370 | |||

S11-100/20 | 100 | 1.4 | 1300*1000*1750 | 200 | 1730/1650 | |||

S11-125/20 | 125 | 1.6 | 1400*1100*1800 | 240 | 2080/1980 | |||

S11-160/20 | 160 | 1.7 | 1450*1200*1850 | 290 | 2540/2420 | |||

S11-200/20 | 200 | 1.8 | 1500*1300*1900 | 340 | 3000/2860 | |||

S11-250/20 | 250 | 2 | 1600*1500*2000 | 400 | 3520/3350 | |||

S11-315/20 | 315 | 2.2 | 1800*1600*2100 | 480 | 4210/4010 | |||

S11-400/20 | 400 | 2.4 | 1900*1700*2200 | 570 | 4970/4730 | |||

S11-500/20 | 500 | 2.7 | 2000*1800*2300 | 680 | 5940/5660 | |||

S11-630/20 | 630 | 3 | 2150*2000*2350 | 810 | 6820 | |||

S11-800/20 | 800 | 3.4 | 2250*2050*2400 | 980 | 8250 | |||

S11-1000/20 | 1000 | 4 | 2400*2200*2450 | 1150 | 11330 | |||

S11-1250/20 | 1250 | 4.5 | 2500*2300*2500 | 1380 | 13200 | |||

S11-1600/20 | 1600 | 5 | 2600*2400*2600 | 1660 | 15950 | |||

S11-2000/20 | 2000 | 5.6 | 2700*2450*2700 | 1950 | 19140 | |||

S11-2500/20 | 2500 | 7.1 | 2850*2650*2800 | 2340 | 22220 | |||

S13 series 20kV three-phase oil-immersed transformer | ||||||||

Model | Voltage Combination(kVA) | Typical Voltage Combinations(kV) | Linkage group labeling | Impedance Voltages(%) | total weight(t) | Reference Size(mm) L*W*H | No-load loss (W) | Load Loss |

S13-30/20 | 30 | High Voltage | Dyn11 | 4 | 0.9 | 1200*950*1400 | 80 | 690/660 |

S13-50/20 | 50 | 4.5 | 1 | 1200*950*1500 | 100 | 1010/960 | ||

S13-63/20 | 63 | 1.1 | 1200*950*1500 | 110 | 1200/1150 | |||

S13-80/20 | 80 | 1.2 | 1200*950*1600 | 130 | 1440/1370 | |||

S13-100/20 | 100 | 1.4 | 1300*1000*1750 | 150 | 1730/1650 | |||

S13-125/20 | 125 | 1.6 | 1400*1100*1800 | 170 | 2080/1980 | |||

S13-160/20 | 160 | 1.7 | 1450*1200*1850 | 200 | 2540/2420 | |||

S13-200/20 | 200 | 1.8 | 1500*1300*1900 | 240 | 3000/2860 | |||

S13-250/20 | 250 | 2 | 1600*1500*2000 | 290 | 3520/3350 | |||

S13-315/20 | 315 | 2.2 | 1800*1600*2100 | 340 | 4210/4010 | |||

S13-400/20 | 400 | 2.4 | 1900*1700*2200 | 410 | 4970/4730 | |||

S13-500/20 | 500 | 2.7 | 2000*1800*2300 | 480 | 5940/5660 | |||

S13-630/20 | 630 | 3 | 2150*2000*2350 | 570 | 6820 | |||

S13-800/20 | 800 | 3.4 | 2250*2050*2400 | 700 | 8250 | |||

S13-1000/20 | 1000 | 4 | 2400*2200*2450 | 830 | 11330 | |||

S13-1250/20 | 1250 | 4.5 | 2500*2300*2500 | 970 | 13200 | |||

S13-1600/20 | 1600 | 5 | 2600*2400*2600 | 1170 | 15950 | |||

S13-2000/20 | 2000 | 5.6 | 2700*2450*2700 | 1390 | 19140 | |||

S13-2500/20 | 2500 | 7.1 | 2850*2650*2800 | 1650 | 22220 | |||

Product Features

- Efficient cooling system: oil-immersed transformers use oil as the main cooling medium, and the transformer temperature is effectively controlled by oil-immersed self-cooling, oil-immersed air-cooling, oil-immersed water-cooling, or forced oil circulation, which contributes to the transformer's stable operation and long-term maintenance.

- Excellent insulating properties: Transformer oil not only plays a cooling role, but also has good insulating properties, reducing insulation distance and lowering costs.

- Strong short-circuit resistance: the fastening measures of windings and cores, as well as the design of non-suspended structure, can withstand the vibration during transportation and operation.

- Temperature control: oil-immersed transformers are operated under specified cooling conditions, equipped with thermometers and possible temperature control systems to monitor the top oil temperature in real time, which usually does not exceed 90°C, ensuring that the safety threshold is not exceeded to prevent insulation aging.

- Low noise: due to the cushioning effect of transformer oil, the oil-immersed transformer has less noise during operation.

- Winding design: Low-voltage windings are usually made of copper-foil-wound cylindrical structure, while high-voltage windings are made of multi-layer cylindrical structure to ensure balanced ampere-turn distribution and reduce magnetic leakage.

- Oil tank design: The oil tank may be designed with corrugated sheet with breathing function to compensate for the volume change of oil due to temperature change, and at the same time prevent the entry of external pollutants.

- Superior sealing performance: oil-immersed transformers emphasize sealing performance to prevent oil leakage and the intrusion of external contaminants.

- Diversity of insulation materials: Insulating cardboard, cable paper, telephone paper and crumpled paper are used as insulating materials, which have excellent insulating properties and durability and provide different insulation protection.

- Environmental characteristics: Although there is a possibility of combustion of transformer oil, modern oil-immersed transformers are designed to take into account environmental requirements, such as the use of vegetable oil as insulation and cooling medium, to meet the high environmental requirements.

- Safety protection devices: including explosion-proof tubes, gas relays, etc., to ensure that the pressure can be released in time to prevent equipment damage in case of internal failure.

- Long-term stability: oil-immersed transformers have better long-term stability and reliability due to the long-term immersion of its insulating oil.

Application scenario

Oil-immersed stacked core transformers are suitable for the following scenarios:

- Used as a voltage booster or voltage reducer in power systems

- Power distribution and transmission in industry

- Power supply and backup power in commercial buildings

- Other locations requiring a stable and reliable power supply

Key words:

Get A Quote

Leave your contact information and get a free product quote

Solution

Become a leader in the power distribution industry in the intelligent era

Related Products

The company mainly operates transformer and distribution equipment such as screens, desks, cabinets, and boxes, as well as transformer and distribution equipment, transformers, switches, automation control systems, etc

● Model: SC(B)12、SC(B)14、SC(B)18 ● Capacity: 30kVA to 2500kVA ● Voltage: 0.4kV, 6kV to 11kV

10kV Three-dimensional Rolled Iron Core Transformer

● Voltage: 400V, 6kV to 10kV ● Capacity: 30kVA to 2500kVA ● Model: S13、S20、S22

0.4\6.6\10\11kV Cast Resin Dry Type Transformer

● Voltage: 0.4kV, 6kV to 11kV ● Capacity: 30kVA to 2500kVA ● Model: SC(B)12、SC(B)14、SC(B)18